Custom Engineered Two-Room Chemical Metering Building Case Study

Fiberglass Protection for Chemical Feed Processes

Updating a Wastewater Treatment Facility

The Blue River Main Treatment Facility in Johnson County, KS, is one of the largest wastewater treatment plants in the Kansas City area. Initially built in the 1960s and later renovated in 1987, the facility relies on an aging infrastructure presently being upgraded. The recent improvements focus on optimizing solids management processes to meet expected capacity and regulatory requirements through 2035.

One part of the project includes enhanced chemical treatment to reduce environmental impacts, including targeting the removal of phosphorous—a pollutant that contributes to harmful algal blooms in natural water bodies.

Chemical Building Keeps Processes Separate

As part of the facility upgrades, the Blue River Main Treatment Facility uses a Shelter Works fiberglass (FRP) chemical storage building to protect the updated ferrous chloride and sodium hypochlorite chemical feed systems. Kevin Guy, Director of Business Development at Haynes Equipment in Olathe, KS, explained that ferrous chloride is a primary chemical for phosphorous removal, reducing nutrient pollution in treated water. Sodium hypochlorite, commonly known as bleach, is used for disinfection and odor control and is vital in enhancing water quality.

Fiberglass is a safer building material for storing chemicals and housing chemical feed systems because fiberglass does not react with most chemicals. It is a long-lasting, durable, chemical-resistant material ideal for corrosive environments.

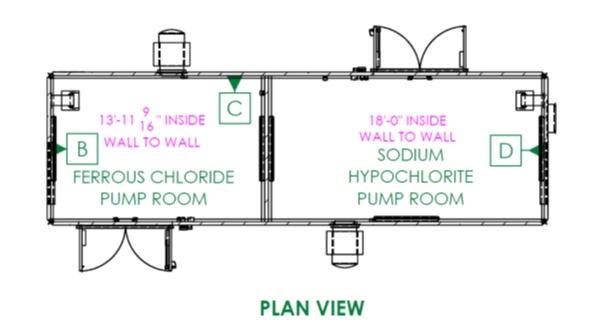

The custom 10' x 32’-8" x 8' chemical metering building includes an FRP encapsulated partition wall that separates it into two distinct sections, providing a controlled environment for each chemical's specific needs, prolonging equipment life, and reducing maintenance requirements. The first room, dedicated to ferrous chloride, houses two peristaltic pumps. The second room, designed for sodium hypochlorite, contains two peristaltic pumps and one diaphragm pump. Each room is equipped with independent entryways, lighting, and HVAC systems, which ensure the separation of processes and provide an added level of safety and efficiency.

Working With Shelter Works

According to Guy, "A well-engineered chemical feed system is key to an effective water treatment program. A properly designed chemical feed and control system ensures safety, operating, and cost management goals are achieved. Having the right enclosure is an important aspect of an effective chemical feed system." Reflecting on the collaboration, he added, "The close collaboration between Haynes Equipment Company, Inc. and Shelter Works was essential to the achievement of the criteria set forth by the engineer and end-user."

By choosing a custom-engineered, two-room fiberglass enclosure, the Blue River Main Treatment Facility ensures the safe and effective handling of chemicals, supporting their goal to meet environmental standards and protect local waterways for years to come.