Compare Shelter Works Shelters to

Non-Structural Fiberglass

Fiberglass buildings with a foam core have a common weakness; the foam.

It is not a good structural material and should not be relied upon to hold together the real structural materials — the fiberglass skins.

That is why all of our fiberglass shelters are built with our proprietary FiberBeam™ Technology. Our shelters do not rely on low density foam for the structural support of the composites that make up our walls, roofs and doors.

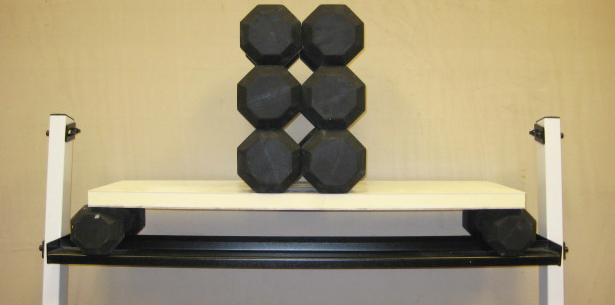

With

Fiberbeam™

Without

Fiberbeam™

There are several manufacturers of FRP (fiberglass reinforced plastic, A/K/A fiberglass) buildings that you might think are all roughly similar in construction- rigid sheets of low density foam laminated between two layers of fiberglass, known as a stressed skin sandwich panel. It has been done like this since the early days of FRP and it makes for a nicely insulated structure. Even Shelter Works used this technique early in its history, until we began experiencing some delamination that we had to fix under warranty. Something had to be done to solve the problem systemically.

We reasoned that no matter how well you bond foam to FRP the bond is only as good as the molecular strength of the weaker of the two materials – the foam. And frankly the foam is not a good structural material and should not be relied upon to ensure the integrity of the building.