Two Room Chemical Feed Building With Containment Basin FloorCase Study

AmeriChem Systems, Inc., located outside of Chicago, IL, custom engineers and fabricates corrosion-resistant chemical feed, containerized, and custom process systems for industrial applications. They recently used a Shelter Works custom fiberglass building to house a complete chemical treatment program that handles the circulating water supply for a cooling tower at a power plant. The chemicals keep the pipes and equipment from scaling or fouling, and controls biological growth in the cooling tower basin.

The fiberglass enclosure has two separate rooms, one for the chemical feed systems and another for the control room. According to Dan Wagner, President of Americhem Systems, the shelter was divided into two rooms because “We were looking to segregate the electrical controls from the chemicals in the pump room. If there were ever a leak or spray of the chemicals, there would be no potential of damaging the sensitive control equipment since we have the interior wall between them”. There is a single man door in the partition wall so the technician can walk between the two rooms without exiting the building.

Pump Room

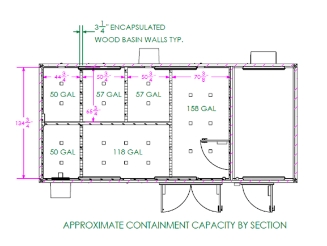

The pump room houses six (6) individual chemical feed systems, sulfuric acid, sodium hypochlorite, sodium bromide, sodium bisulfite, scale inhibitor, and dispersant. The area has a 4” deep containment basin floor with an FRP grated walking surface. The containment basin has six compartments, one for each chemical, with through-wall drains.

Other customizations to the pump room include bulkheads for routing the inlet and outlet process lines to the exterior of the building, a heater to keep the space comfortable and prevent the chemicals from freezing, exhaust fans to circulate fresh air into the room and prevent fumes from becoming potentially hazardous, and skylights to supplement and soften the artificial light provided by the interior LED lighting.

Control Room

The control room houses the main PLC (Programmable Logic Controller) panel that drives the operation of the chemical feed systems, the 480V and 120V power distribution panels for the feed, and the building's automation systems. Instead of a containment basin floor, the control room has a 1/8” diamond plate floor powder coated in a neutral gray color. This room has a one-ton air conditioning unit to prevent the electrical components inside the panels from overheating during the summer months.

The shelter was manufactured wood reinforcement in the walls for hanging heavy equipment and 2” foam in the roof and walls for an R-Value of 15. Each room contains emergency exit lighting, while the exterior has security lighting above the doors. The entire building is mounted on a steel base skid with lifting eyes for moving the enclosure. The base skid allows the client to place the building on an existing concrete pad with minimal civil changes to their existing infrastructure.

The Shelter Works Experience

This chemical feed building with separate control and pump rooms is another example of how Shelter Works can provide multiple solutions within a single enclosure. Wagner said that collaborating with Shelter Works "truly felt like a partnership. Working with the custom nature of our equipment, Shelter Works teamed with us seamlessly to make the necessary changes and revisions during the submittal process to help keep the project on track." The result is a fully customized product to meet the end user’s needs.