Shelter Works Fiberglass Enclosures for Remote Telecom Applications

The telecommunications industry relies on its infrastructure to ensure uninterrupted service to its customers. Damage to sensitive electronics can impact network stability and cause service interruptions that disrupt communication for individuals, businesses, and emergency services. Reliability is a top priority because downtime can lead to significant financial losses, expensive repairs, and potential regulatory penalties. Protecting critical ground-based field equipment from environmental hazards is a primary concern for network operators with field equipment in remote locations. Additionally, the challenges of maintaining and repairing equipment in hard-to-service areas underscore the need for durable, low-maintenance protective enclosures.

Performance in Extreme Environments

Shelter Works prefabricated fiberglass enclosures have been successfully deployed in some of the most inhospitable locations, including a remote region outside Ontario, Canada, south of the Arctic Circle, where one shelter serves as a microwave repeater station. The shelter ensures reliable operation in a region where temperatures can drop as low as -45°F and average annual snowfalls exceed 100”. The extreme cold, heavy snowfall, and lack of road access necessitate a shelter that is durable enough to withstand harsh conditions while being lightweight for easy transportation and installation.

Thermal Stability and Insulation

Remote telecom sites in colder territories like this one need enclosures with superior insulation to maintain stable internal temperatures. Shelter Works custom designed the 8’-4” x 24’-8” x 8’ microwave repeater station with 6-inch-thick foam insulation in the walls and roof, providing an estimated R-value of 39. Unlike metal enclosures, Shelter Works fiberglass construction does not have thermal conductors like wood or steel studs that promote heat loss. Instead, they incorporate FiberBeam™ technology, using fiberglass studs spaced 12 inches apart and integrated into the walls and roof for structural support. This design prevents heat loss and ensures sensitive telecommunications equipment remains protected from freezing temperatures.

Remote telecom sites in colder territories like this one need enclosures with superior insulation to maintain stable internal temperatures. Shelter Works custom designed the 8’-4” x 24’-8” x 8’ microwave repeater station with 6-inch-thick foam insulation in the walls and roof, providing an estimated R-value of 39. Unlike metal enclosures, Shelter Works fiberglass construction does not have thermal conductors like wood or steel studs that promote heat loss. Instead, they incorporate FiberBeam™ technology, using fiberglass studs spaced 12 inches apart and integrated into the walls and roof for structural support. This design prevents heat loss and ensures sensitive telecommunications equipment remains protected from freezing temperatures.

Customization for Remote Telecom Needs

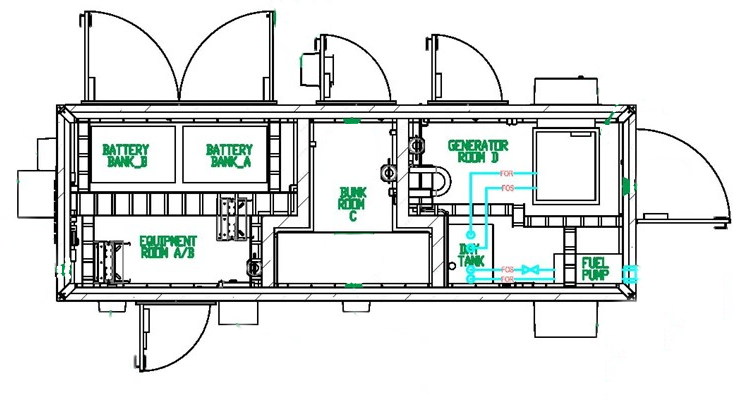

Given the absence of commercial electricity, this shelter relies on dual 48VDC generators and an extensive battery bank, with external diesel tanks providing enough fuel for 3–4 months of continuous operation. Shelter Works was able to custom manufacture the shelter to include three rooms divided by walls comprised of 3.5” insulation and 1-1/4” of gypsum board on each side of the insulation, encased in fiberglass. Each section has its own points of ingress. The first room houses telecom equipment and batteries. The equipment in the room subdivides it into two separate sections necessitating separate entry for each. The batteries are accessed by a set of double doors and the equipment room portion is entered by a single man door on the opposite wall of the shelter. The second room provides small living quarters with wall-mounted bunk beds for stranded service technicians and the third serves as a generator room with two points of entry.

The shelter also includes a foam insulated C10 perimeter channel steel base skid with C8 cross supports. The skid allows for placement on terrain without a prepared foundation.

Durability and Structural Integrity

Shelter Works manufactures fiberglass shelters that are sturdy enough to endure extreme weather conditions. Shelter Works' proprietary FiberBeam technology gives the enclosures a superior strength-to-weight ratio, making them stronger than steel while remaining lightweight. This structural integrity is essential in environments prone to heavy snow loads and high winds, ensuring network stability and preventing service interruptions due to structural failure.

The shelter was manufactured using Class 1 fire retardant gel coat, Elfoam insulation, wood reinforced interior walls and roof, and gypsum lined divider walls to meet the required fire barrier standards.

Lightweight and Easy Transport

Deploying shelters to isolated areas can be challenging due to transportation costs and accessibility. Fiberglass enclosures are significantly lighter than their metal counterparts, reducing transportation expenses. In the case of this shelter, it was transported via rail to the nearest town and loaded onto a truck for the final leg of the journey along a man-made ice road. The reduced weight simplified loading and off-loading, enabling efficient delivery to an otherwise inaccessible location.

Security and Corrosion Resistance

Traditional metal enclosures are prone to corrosion in harsh and damp environments, requiring frequent maintenance. Fiberglass shelters do not rust, rot, corrode, or decay, making them virtually maintenance-free. Additionally, the seamless Shelter Works design deters damage from wildlife, an essential consideration in regions where polar bears are known to tear the siding off metal buildings. These attributes, along with reinforced locking mechanisms, ensure long-term equipment protection and uninterrupted network performance.

Fiberglass enclosures provide an optimal solution for remote telecom applications, offering superior durability, environmental resistance, thermal stability, and security. Their lightweight design facilitates easier installation in challenging locations, while their long-term reliability reduces maintenance costs. As telecom networks expand into remote areas, fiberglass enclosures will continue to play a vital role in maintaining uninterrupted service and protecting critical communication equipment from environmental and physical threats.