Protecting Electrical Equipment in a Harsh Chemical EnvironmentCase Study

Protecting Electrical Equipment in a Harsh Chemical Environment

A commercial battery recycling plant in the Gulf Coast region uses smelting to turn lead acid batteries, scrap lead, and wheel weights into refined lead alloys. The plant faces ongoing challenges with equipment degradation due to constant exposure to residual caustic dust and high humidity.

Their operations rely on the power distribution center's ability to provide consistent service to their systems. The metal enclosures they originally used to house their SCADA, POC, and other computer equipment required frequent maintenance and showed early signs of corrosion. The facility's plant manager needed a low-maintenance solution that would be easy to install and provide long-term protection for their sensitive computer equipment.

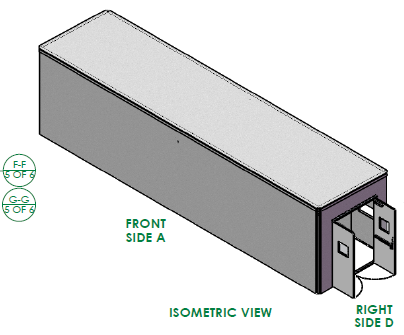

The enclosure is mounted in an area constrained by the equipment around it. Accommodating these limitations necessitated a shelter that had to be long and narrow, measuring 10' x 40'x 10’-6" (h), with access doors on each end.

To address these issues, the facility selected a custom fiberglass equipment shelter from Shelter Works that could easily be engineered to meet the limitations of the allotted space while providing reliable protection from the plant's environment.

Corrosion Resistance + Structural Integrity

Designed with longevity, durability, and energy efficiency in mind, the shelter offers multiple advantages over its metal alternatives. The enclosure was manufactured using Shelter Works' proprietary FiberBeam™ technology, incorporating vertical fiberglass I-beams every 12 inches on center throughout the walls and roof. By securing the interior to the exterior of the walls with fiberbeams, Shelter Works can eliminate the risk of delamination. This advanced composite design provides a durable, low-maintenance solution with the strength of steel without corrosion.

Improved Thermal Performance

The shelter was manufactured with 2" rigid insulation in both the roof and walls, achieving an R-value of 15. This helps to regulate internal temperatures and reduce the workload on HVAC equipment, improving energy efficiency and system reliability.

Easy Installation

One key factor in the decision-making process was the ease of offloading and placement. The factory-built customizations made the installation of onsite equipment easier, reducing overall construction costs:

- The submittal process determined the placement and sizes of the formed openings that allowed for the field installation of two wall-mounted air conditioners. Formed openings eliminate the structural integrity issues that can arise when a wall is cut into, exposing insulation to the elements.

- Predrilled holes spaced 24" apart on the internal flange enabled precise anchoring to the facility's existing concrete pad.

- The roof included a 19/32" OSB on the interior portion to support the field-installed cable ladder.

These built-in features reduce installation labor, ensure structural integrity, and help the contractor complete the project on time and under budget.

Reliable Equipment Protection and Long-Term Value

With the Shelter Works fiberglass enclosure, the facility now benefits from:

- Improved protection of critical control equipment

- Minimal maintenance of the exterior and interior surfaces

- Longer service life and lower lifetime cost of ownership

- Simplified installation and reduced construction costs

The plant manager reported improved climate stability and peace of mind, knowing their critical operations are protected in the plant's challenging conditions.